Vulcan used at Sinopec Shengli Oilfield to improve energy transfer and remove mineral scaling

Vulcan used at Sinopec Shengli Oilfield to improve energy transfer and remove mineral scaling

After 6 months of using the Vulcan electronic descaler the Sinopec Shengli Oilfield does not have to use chemical to manage scale build up in water heating tubes. The company saved costs in energy, labor, maintenance, and no longer deals with their heating system being compromised by heating efficiencies.

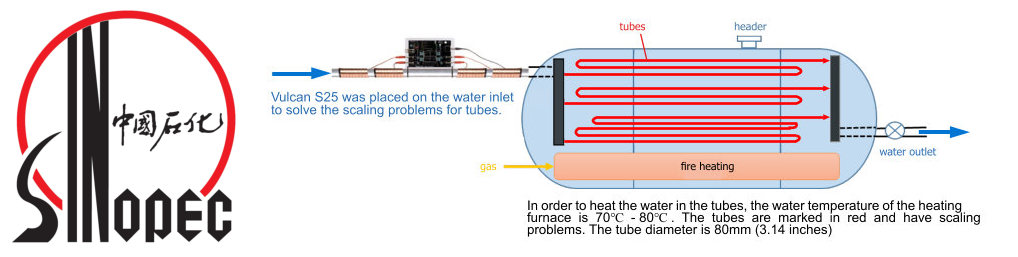

Model: Vulcan S25

Location: City (China)

Installation Area: The water inlet pipe to the heating furnace

Installation Purpose

Gas heats the water in the furnace, the hot water then heats the tubes to raise the water temperature between 40 °C to 70 °C. The water in the tubes pass through the pump and is transported to various wells.

Gas heats the water in the furnace, the hot water then heats the tubes to raise the water temperature between 40 °C to 70 °C. The water in the tubes pass through the pump and is transported to various wells.However, the heat exchanger efficiency continuously decreases because of scale in the tubes. More gas has to be used to heat the furnace, increasing energy consumption.

Our geographic area is prone to extremely high calcium (Ca) content in the water: 1,469.09 mg/L (85.9 GPG). We constantly had to use a variety of cleaning agents because of the high mineral content and we easily measure the decreasing tubes diameter caused by mineral scaling. It was very costly to try and keep the water temperature at 60 °C -70 °C because scaling prevented heat transfer.

Every 3 months, the heating efficiency would be reduced by 50% or more. After 1 year our company had to manually clean all the pipelines. This process was time consuming, costly, and reduced our production capacity.

We decided to install the Vulcan descaler to measure the impact for ourselves on our production facility at Station 20, Xian-he oil production plant, Sinopec Shengli Oilfield.

Installation Observation

After 6 months with 1 Vulcan S25 installed on a test area we found there was no additional electricity usage. More impressively, the overall heat exchanger efficiency was still at 80% after 6 months. We have decided to invest in a holistic approach to managing our scaling problems by incorporating more units throughout the facility.

Before installing Vulcan, the rust and pipe insulation were removed and the impulse bands were winded on the pipe. Then, the outer insulation was put back on.

Outdoor installation with self-made cover to protect the unit from the wind and sun.