FAMU/FSU College of Engineering

FAMU/FSU College of Engineering

By August 20th, about a month after installation, the green biofilm had almost completely disappeared from the surfaces in contact with the Vulcan-treated water. The Vulcan does not change the water quality beyond its effect on its propensity to cause scale buildup.

Model: Vulcan S250

Location: Florida (United States)

Installation Area: Installed on the 10 inch diameter line that feeds twin cooling towers (CT-1 and CT-2)

Objectives

The objectives are to prevent scale buildup on the cooling towers, remove the existing scale, eliminate the need for chemicals or time-consuming cleaning procedures, and to reduce energy costs.History

The maintenance for these cooling towers previously involved continuous injection of descaling chemical cleansers. The use of these cleansers was discontinued over a year prior to the installation of the Vulcan. In that time, the cooling tower flutes became encrusted with both scale and biofilm. Throughout the time period described below, there were no cleaning procedures in place with these cooling towers besides the treatment provided by the Vulcan.Observations over time after the Vulcan Installation

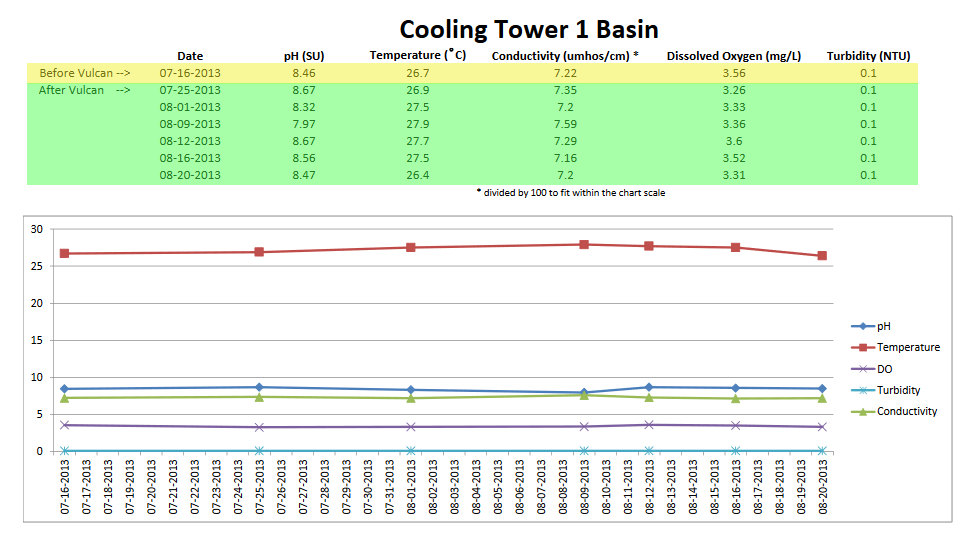

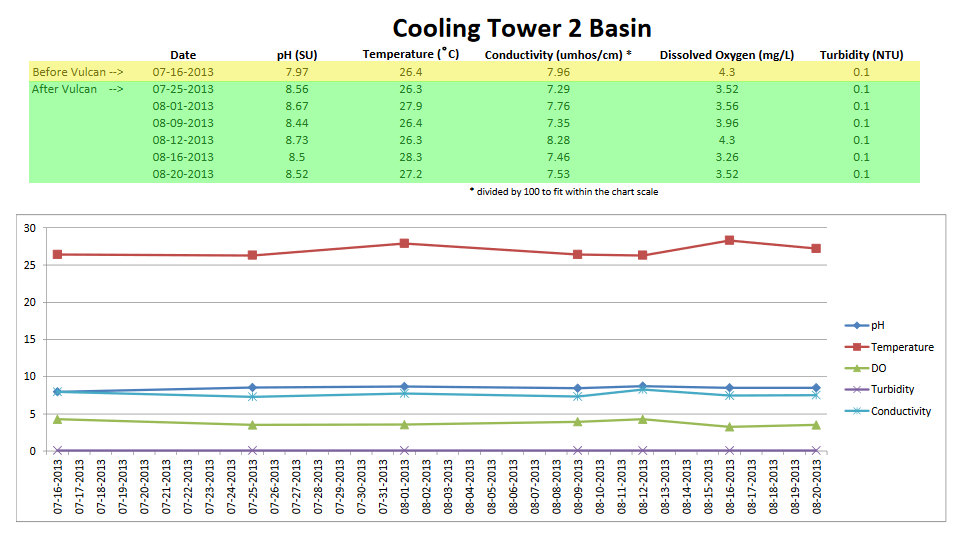

Between the time of the installation on July 16th and examination on August 1st, the green biofilm had begun to recede and gradually disappear. The next visit was about 3 weeks after the installation, on August 9th. At that point, the green biofilm had been further reduced and the scale deposits had begun to separate from the flutes in coin-sized flakes. By August 20th, about a month after installation, the green biofilm had almost completely disappeared from the surfaces in contact with the Vulcan-treated water. The flakes of scale previously observed had fallen off in most places. The cooling tower flute surface area covered with scale deposits had been decreased by over 60%. We are very optimistic about continued improvement with this application. In addition to these observations, water quality measurements were also obtained from each cooling tower and are summarized in the following charts.Data and Observations of the Effects of the Vulcan Electronic Descaler on Cooling Towers

The Vulcan does not change the water quality beyond its effect on its propensity to cause scale buildup. As illustrated below, the pH, conductivity, dissolved oxygen level, and turbidity remained relatively constant during observation from before the installation to over a month after. Temperature is included, because of its effect on the other measurements and seems to correlate with the slight fluctuations observed.In general: The presence of more oxygen in the water results in less mineral scale problems.

During the electrophoresis process a small amount of H2O2 is liberated and H2O2 passivates metal surfaces (referring to a material becoming less affected or corroded by the environment of future use); similar to the passivating process of stainless steel. The Vulcan descaling water treatment will passivate the surface of iron and other metal pipes and surfaces. When passivated these metal surfaces do not oxidate as before and it means less rust and corrosion occurs leading to less deterioration from inside pipes and on surfaces.

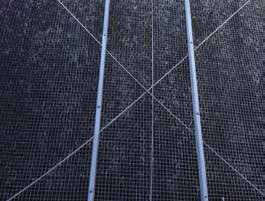

Vulcan S250 installed on a 10 inch diameter line that feeds twin cooling towers (CT-1 and CT-2)

This photo was taken of the inside of CT-1. It illustrates clean flutes that are in constant contact with Vulcan-treated water and a few dry (untreated) areas that still have some remaining green biofilm.

The photographs above were taken of CT-1 about 3 weeks after the Vulcan was installed.

These photos were taken of CT-1 after about 6 weeks.