The X-Pro1 model is a large industrial sized water anti mineral scale system designed for demanding applications on pipes

up to 30 inch diameter. Graded as

unlimited GPM water flow rate and successfully used in power plant applications where water flow has been measured at

2949 m³/h (12,984 GPM). The X-Pro1 model is programmable to allow for individual calibrations according to the pipe material and diameter.

Stops, prevents and removes hard water scaling

Stops, prevents and removes hard water scaling

Solves rust problems

Solves rust problems

Gently sanitizes your water pipe system

Gently sanitizes your water pipe system

Protects whatever your water touches from hard water corrosion

Protects whatever your water touches from hard water corrosion

Eco-Friendly solution that does not use salt or chemicals

Eco-Friendly solution that does not use salt or chemicals

Important minerals remain in the water

Important minerals remain in the water

Lower facility cleaning, repairs and maintenance and labor costs

Lower facility cleaning, repairs and maintenance and labor costs

Supports circular economy practices

Supports circular economy practices

{tab=Electronic Anti-Scale Technology}

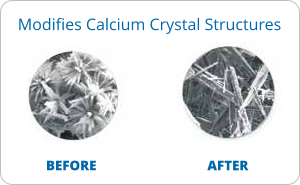

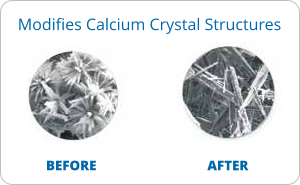

"Wobbling impulse frequency technology designed to alter the molecular construction of hard water minerals from sticky spheres into powerful rod structures to remove scale, sanitize pipes, improve energy efficiency and protect your assets."

Stops

Stops the natural elements found in water from depositing rust and water scale in water pipes, appliances, commercial equipment and whatever your water supply touches.

Gently sanitizes

Gently sanitizes your water pipe system and whatever your water touches; by breaking down rust, scale and limestone deposits on a molecular level and removing it through natural water flow

Protects

Protects your piping, equipment and whatever else your water touches from corrosion and perforation damage of hard water

{tab=X-Pro 1 Model}

Perfected over the past 30+ years to prevent scale minerals from bonding to surfaces and to remove existing scale buildup.

Perfected over the past 30+ years to prevent scale minerals from bonding to surfaces and to remove existing scale buildup.

The state-of–the-art Vulcan electric impulse frequency descaler is an eco-friendly water treatment device that has been perfected over the past 30+ years to prevent scale minerals from bonding to surfaces and to remove existing scale buildup. Removing mineral scale promotes energy efficiency while promoting equipment longevity through circular economy practices.

| Maximum Pipe Diameter |

30 inches |

Maximum Water Flow

|

unlimited GPM

|

| Voltage |

36 Volts |

| Wattage |

3.75 Watts |

| Impulse Band Length |

82' each (12 bands) |

| Band Width |

1.6 inches |

| Frequency Range |

3-32 kHz |

| Required Space |

18' 5" |

| Measurements (electronic unit) |

13.4" x 9.4" x 2.0" |

| Programs |

10 |

Electronic Switching Power Supply Unit |

| 87-260 Volt | 50-60 Hz |

In |

| 36 Volt | 600 mA |

Out |

{tab=Case Study}

Power plant heat pump station and the Vulcan X-Pro series

Power plant heat pump station and the Vulcan X-Pro series

Vulcan X-Pro series electronic mineral descalers were installed in a thermal power plant heat pump station to prevent the scale from reducing the heat exchange efficiency.

Platinum Green Building Certification from LEED

Platinum Green Building Certification from LEED

Energy Complex has been awarded the highest level of

Platinum Green Building certification from LEED (Leadership of Energy and Environmental Design) for energy conservation, harmonious coexistence of industry and the environment and optimal utilization of resources.

{tab=Installation}

The Vulcan Electronic Descaler is a Do-It-Yourself installation. Once installed it does not require maintenance.

The Vulcan Electronic Descaler is a Do-It-Yourself installation. Once installed it does not require maintenance.

Installation Notes:

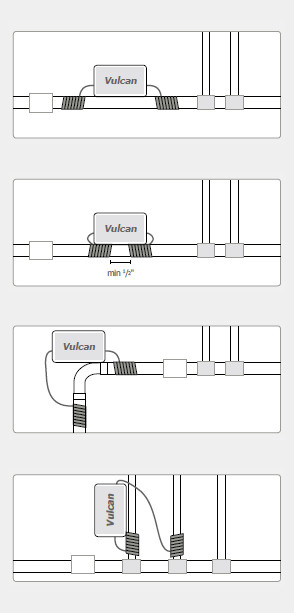

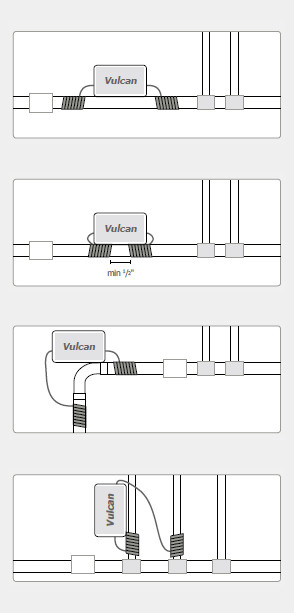

For optimal water treatment it is best to install the Vulcan Descaler near the water meter or at the main water supply.

It can be installed vertically, horizontally or at any other angle. If there is no space available on the pipe the device can also be wall-mounted.

The impulse bands can be wound awound a pipe on the left side, on the right side or underneath the electronic device. In the event of limited space; the windings can be placed partly on the main pipe and partly on the distributor pipe; the treatment impulses extend over several meters to either side of the pipes. Temperature peaks on heating element surfaces should not exceed ~203°F .

Leave a safe distance of at least ½ inch between the bands. Do not remove the end caps or the impulse band insulation. Do not cut the impulse bands or the 24 V power cord of the power supply unit.

Use the provided electronic switching adaptor only. Protect the electronic unit and the power supply against direct water. Only specific Vulcan units (produced on demand) can run under water. ONLY use water to clean the Vulcan device.

The operating temperature of Vulcan ranges from -13°F to 122°F.

Installation Steps:

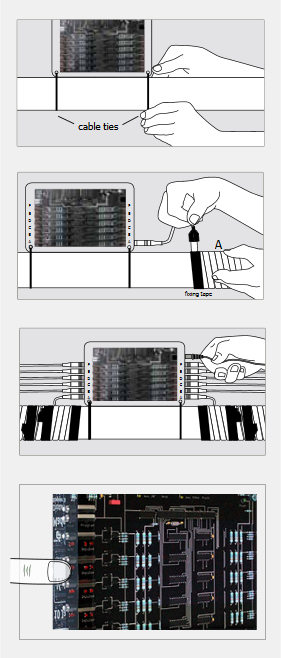

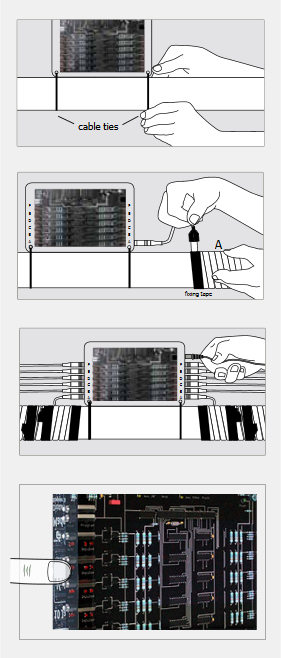

1. Put the cable ties through the fixing holes at the bottom of the electronic device. Now place the device onto the pipe. Use the cable ties to fix the device to the pipe.

2. Plug now impulse band A into the bottom impulse band in-jack A and latch it to the pipe with the fixing tape.

3. Wind the impulse band around the pipe producing a coil. Make sure you wind the band tightly to the pipe and place the windings close to each other.

4. Latch the end of the band to the pipe with the fixing tape.

5. Plug the other impulse band A into the in-jack on the opposite side and repeat the steps 2 - 4.

6. Plug impulse band B into the next impulse band in-jack B and repeat step 2 - 5 until all impulse bands are in use. All impulse bands must be wound tightly around the pipe and fixed with the fixing tape.

7. First plug the connector into the upper right in-jack of the device and then connect the power supply unit with an electrical outlet.

8. Programming: Set the program by touching the twin metal sensors on the left side simultaneously

{slider=Installation Check List}

Has the installation location been chosen with respect to these factors?Time Factor (water in tanks max. 48 h)

Heat Factor (Temperature peaks on heating element surfaces should not exceed ~203°F)

Distance Factor (max. 2 km / 1.24 mile pipeline length)

Are there unusual high levels of certain substances in the water? If yes, have they ben taken care of?Example: Iron (Fe) and other metals: The content of iron and other metals in the water should not exceed 1 mg/l (1 ppm).

Other metals, for example: copper(Cu), aluminum(Al), lead(Pb), nickel(Ni), Zinc(Zn) can affect the Vulcan treatment.

Mn: The manganese level should not exceed 0.1 mg/l (0.1 ppm)

Have filter and pumps locations of been taken into consideration?As a general rule it is better to install Vulcan after a pump and after a filter, if the setting in your installation area allows it.

Filters: Crude filters (> 50 μ) do not remove the mono-crystals and can be ignored. For more sensitive filters ( < 50 μ). it is recommended to install Vulcan after the filter.

Pumps: If possible, we advise installing Vulcan after any pumps.

WHY? : Pumps with internal plastic wheels may create an electrical field that may affect the electronic impulse results of the descaler. Pumps with internal metal wheels may also cause an effect on the altered hard water molecules. If you know your pump does NOT create a very strong electrical field then install the Vulcan device before the pump on your main water line. If you are uncertain install after your main water pump.

Filters: If possible, we advise installing Vulcan after any pumps.

WHY?: Water filters are manufactured in a very wide variety of membranes and mediums; very small membrane water pathways can potentially filter out the treated hard water crystals. In general, install the Vulcan after your main water filter system.

Have you checked for strong electricity, magnetic fields or electro-motors?Please make sure that there are no strong electric lines running close to the installation area. High voltage electric lines or strong magnetic fields may interfere with the Vulcan impulse-field. Please install Vulcan approximately 1 ½ to 3 feet away from these fields.

Are paint or cover materials on the pipe taken care of?Thin coatings such as pipe protection (e.g. corrosion protection paint) are suitable to place the impulse-bands directly on top.

Insulation material or other thicker protective layers should be dismantled and can be re-installed over the impulse bands after installation.

Is the pipe surface temperature suitable?The pipe’s outside temperature should not exceed ~ 149° F. Above this may harm the isolation of the copper impulse bands.

{/slider}

{/tabs}