Cooling Tower- Cost Savings and Physical Water Treatment with Vulcan

Cooling Tower- Cost Savings and Physical Water Treatment with Vulcan

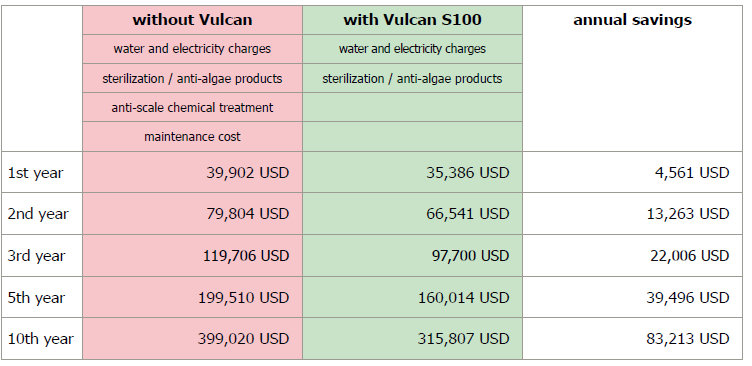

Under 1 year, with the Vulcan treatment it has already cost less than full chemical treatment

Model: Vulcan S100, Vulcan S25

Location: Japan

Installation Area: cooling tower for 100RT turbo chiller, 24-hour yearly operation

Pipe Diameter: 150 A

Effect: chemical treatment reduced

Full Chemical-treatment vs. Vulcan-treatment Indicates: Within the first year of incorporating the Vulcan device, this company had saved more on maintenance over the initial cost of the device.

Further Benefits

Electric Saving: about 5-15%, by the scale prevention on the turbo chillerGas Saving: about 5-25%, by the scale prevention on the absorption chiller

Equipment Life Extension: about 30-60%

Physical Water Treatment as the Solution for Cooling Towers

Physical Water Treatment as the Solution for Cooling Towers

Test report on Vulcans (pulsed water treatment systems) installed as a preventive measure against scale buildups causing faulty of the cooling towers

Tested Field: Factory of a pharmaceutical company

Installation Sites: Cooling towers on the rooftop of the second building

2-1 cooling tower A: Makeup water piping size is 50A.

2-2 cooling tower B: Makeup water piping size is 50A.

1 cooling tower C: Makeup water piping size is 50A and circulating piping size is 80A.

Model installed: Vulcan S25

(water treatment capacity: 25 m3/hour)

Date installed:

July 22, 2006: cooling towers A, B, and C

October 6, 2006: cooling tower C

Objectives:

1 To prevent scale buildups on the cooling towers.

2 To reduce chemicals used for water treatment

(measure for complying with ISO 14001)

3 To save the energy cost by preventing the deterioration of the heat exchange effectiveness

(water treatment capacity: 25 m3/hour)

Date installed:

July 22, 2006: cooling towers A, B, and C

October 6, 2006: cooling tower C

Objectives:

1 To prevent scale buildups on the cooling towers.

2 To reduce chemicals used for water treatment

(measure for complying with ISO 14001)

3 To save the energy cost by preventing the deterioration of the heat exchange effectiveness

Vulcan installed on the makeup water piping (50A). Used for cooling towers A, B and C

Vulcan installed on the circulating piping (80A). Used for the cooling towers C

Verification of the effectiveness:

After installation of the Vulcans, the statuses of the cooling towers A, B, and C were inspected without using any water treatment chemicals. Even after elapse of approximately six months, almost no scale build-ups were observed inside the refrigerators and the heat exchanger tubes, and no water pollution warning was displayed. (Usually, without water treatment chemicals, the water quality is deteriorated and water pollution warning is displayed.) Silica adhered on the cooling towers was easily removed with a finger. With these results, the effectiveness of the installation of the Vulcans could be confirmed.

Remarks (Summary):

Vulcan changes only the crystal structure of scales without changing the quality of water. Therefore, nothing is added or reduced to or from the ingredients of water. The water through Vulcan is soft and has an increased permeability. Vulcan can be used as better cooling water.(*) The effectiveness of the water treatment in the water supply line will last for 2-7 days and for approximately 1 mile/ 2 km in distance.

Major features include:

- Prevents buildups of rusts and scales

- Makes cleaning in the kitchen and bathroom much easier (toilets, showers, tiles, joints, etc.)

- Drastically reduces the clogging due to oil balls

- Eliminates the necessity of strong chemicals for removing scales.

- Eliminates the necessity of additives.

- Does not change the water quality.

- Prevents the clogging at the time of drainage

Test report on Vulcans (pulsed water treatment systems) installed as a preventive measure against scale buildups causing faulty of the cooling towers

Test report on Vulcans (pulsed water treatment systems) installed as a preventive measure against scale buildups causing faulty of the cooling towers

Cooling Tower A / Cooling Tower B

Cooling Tower C

Developments after installation of the Vulcan

Adhesion of silicia six month after the installation of the Vulcan

Adhesion of silicia six month after the installation of the Vulcan

water is hosed

BEFORE: Silica cannot be removed with a water hosing; it has to be scrapped off.

AFTER the hosing

AFTER: Silica is removed by simply spraying the unit with a water hose. (The remaining silica is pealed off with a touch of a finger.)