Contact Waslix (This email address is being protected from spambots. You need JavaScript enabled to view it. | 412-848-5058) for a comprehensive installation plan for your building.

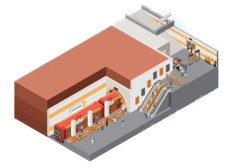

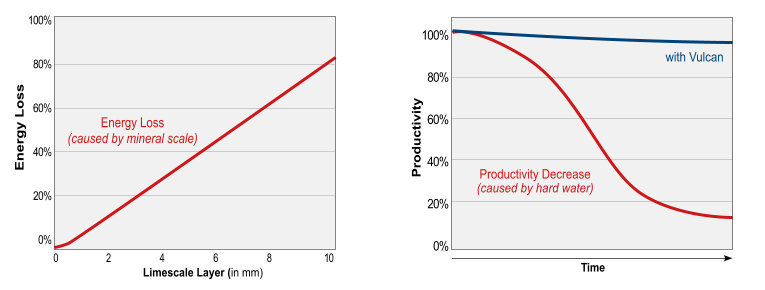

* Sizing an appropriate mineral descaler model/s is a combination of the building’s primary use, diameter of the water pipes where the mineral descaler will be installed, and the anticipated water flow. Other variables such as building height, square footage and supporting equipment (boilers, heat exchanges, cooling tower, etc.) also play a role in developing a holistic descaling plan to lower energy consumption and extend equipment and piping infrastructure lifespans.

Note: to offer a general mineral descaling model sizing plan for the building classifications below, assumptions were made for pipe diameter, number of floors, building size, etc. A final installation plan for your specific building may require more or fewer installed models.

U0 – Utility Company Land And Building

|

Mineral Descaling Models: |

| Installation Considerations: Similar to an office building environment interested in removing mineral scale from building support equipment to decrease their energy demands. |

| • Energy Efficiency Studies • Office Buildings |

U1 – Bridge, Tunnel, Highway

| Installation Considerations: Not applicable |

U2 – Gas or Electric Utility

|

Mineral Descaling Models: |

| Installation Considerations: Mineral descaler inclusion would be limited to support water supply in an administrative building. |

| • Energy Efficiency Studies • Office Buildings |

U4 – Telephone Utility

|

Mineral Descaling Models: |

| Installation Considerations: Similar to an office building environment interested in removing mineral scale from building support equipment to decrease their energy demands. |

| • Energy Efficiency Studies • Office Buildings |

U5 – Communication Facility

Other Than Telephone

|

Mineral Descaling Models: |

| Installation Considerations: Similar to an office building environment interested in removing mineral scale from building support equipment to decrease their energy demands. |

| • Energy Efficiency Studies • Office Buildings |

U6 – Railroad

Private Ownership

| Installation Considerations: Not applicable |

U7 – Transportation

Public Ownership

| Installation Considerations: Not applicable |

U8 – Revocable Consent

|

Mineral Descaling Models: |

| Installation Considerations: Contact us so we can learn more about your building and develop a custom installation plan. |

| • Energy Efficiency Studies • Office Buildings |

U9 – Miscellaneous Utility Property

|

Mineral Descaling Models: |

| Installation Considerations: Contact us so we can learn more about your building and develop a custom installation plan. |

| • Energy Efficiency Studies • Office Buildings |

Without knowing the intrinsic specifications for your property classification, the examples above are offered as a possible solution. However, this may not be completely accurate until the above-mentioned variables are considered.